Cantor ERP+CIM

A system that grows with your company

All items in just one order

Customer satisfaction thanks to reliable scheduling

Leaner, optimized processes

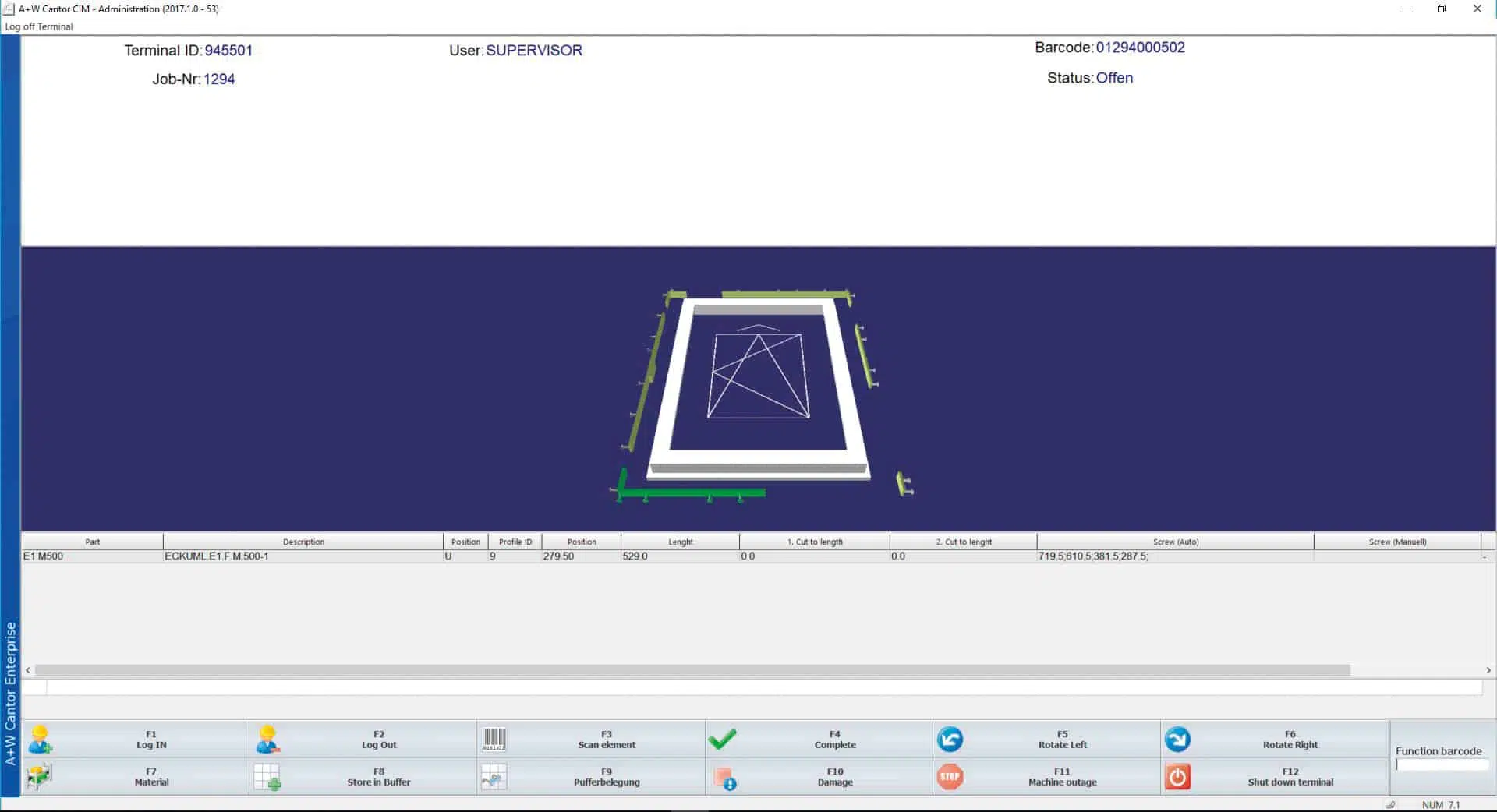

Increase productivity with workstation monitors

About the Product

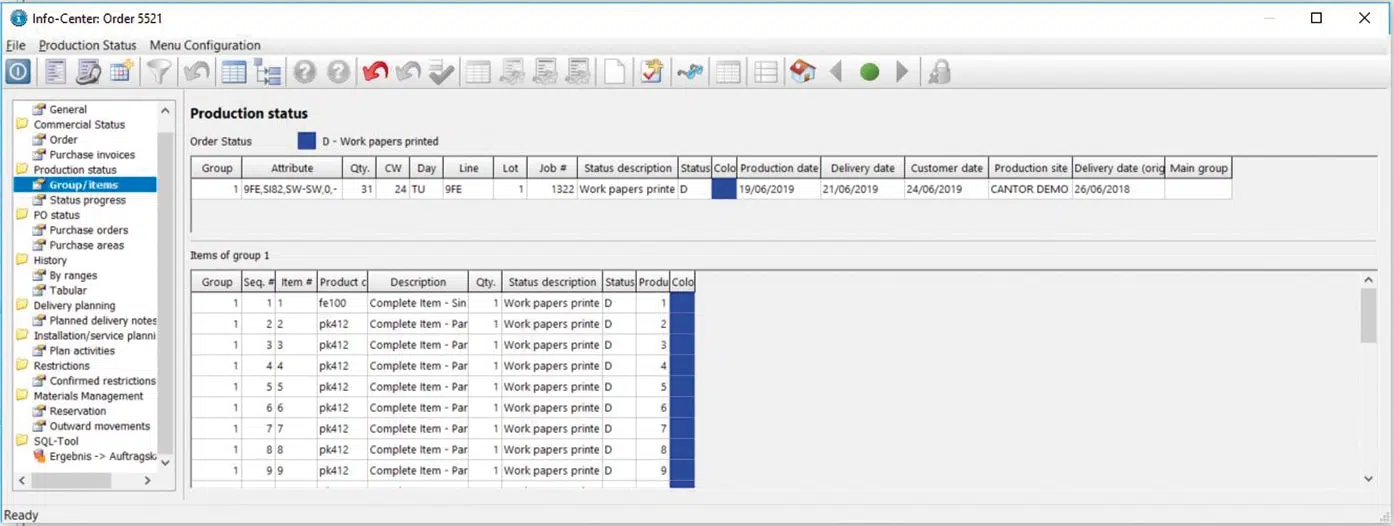

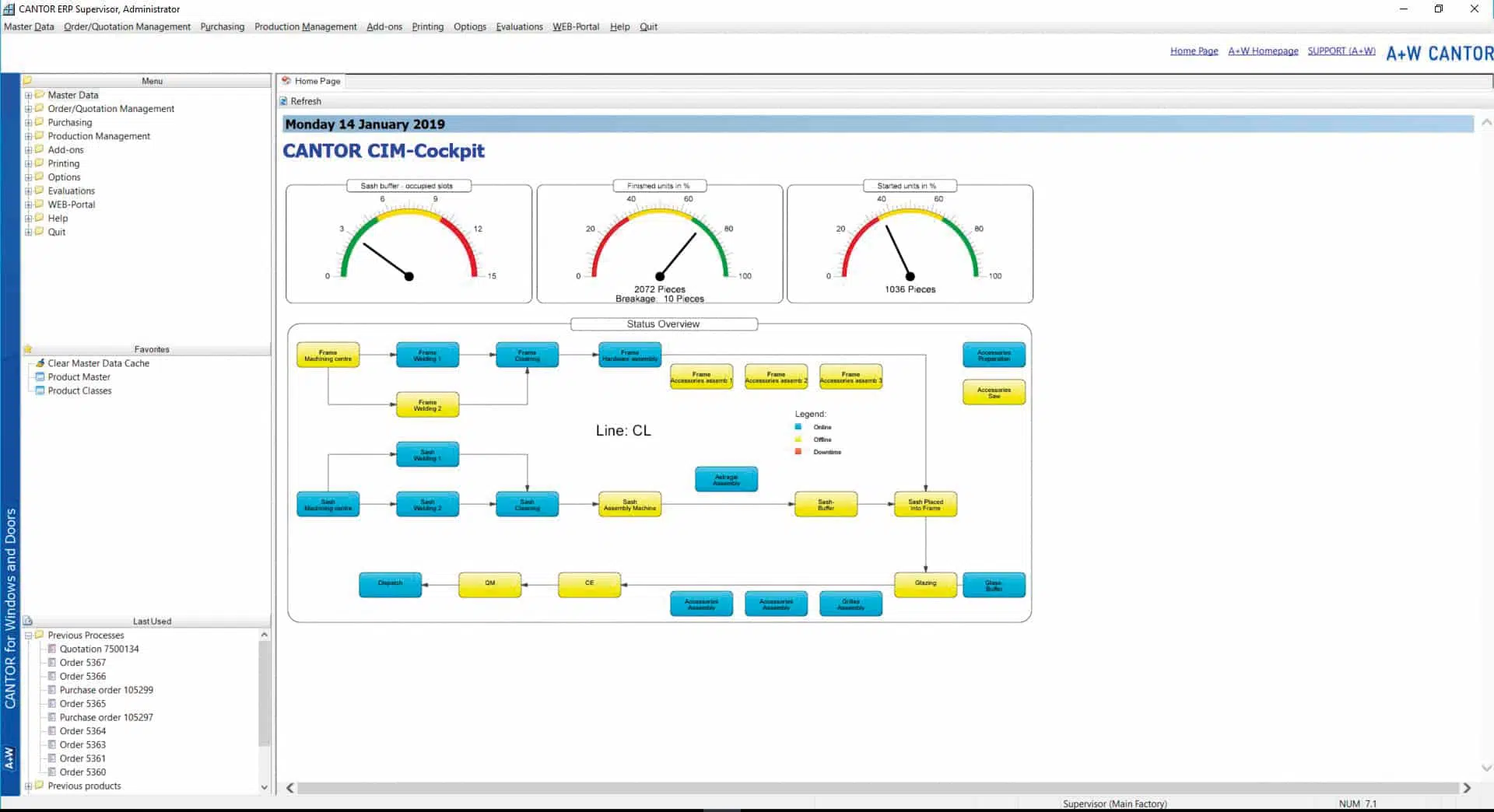

A+W Cantor provides transparency for companies, extending seamlessly from initial stages through to production, shipping, and subsequent service and installation planning. This framework enables continuous oversight, allowing for adherence to schedules and meeting specific requirements. Real-time tracking of order statuses enables prompt and accurate responses to customer inquiries, eliminating the need for manual search through paper documents in production processes, thus enhancing efficiency .

ERP – Integrated Modules & Business Processes

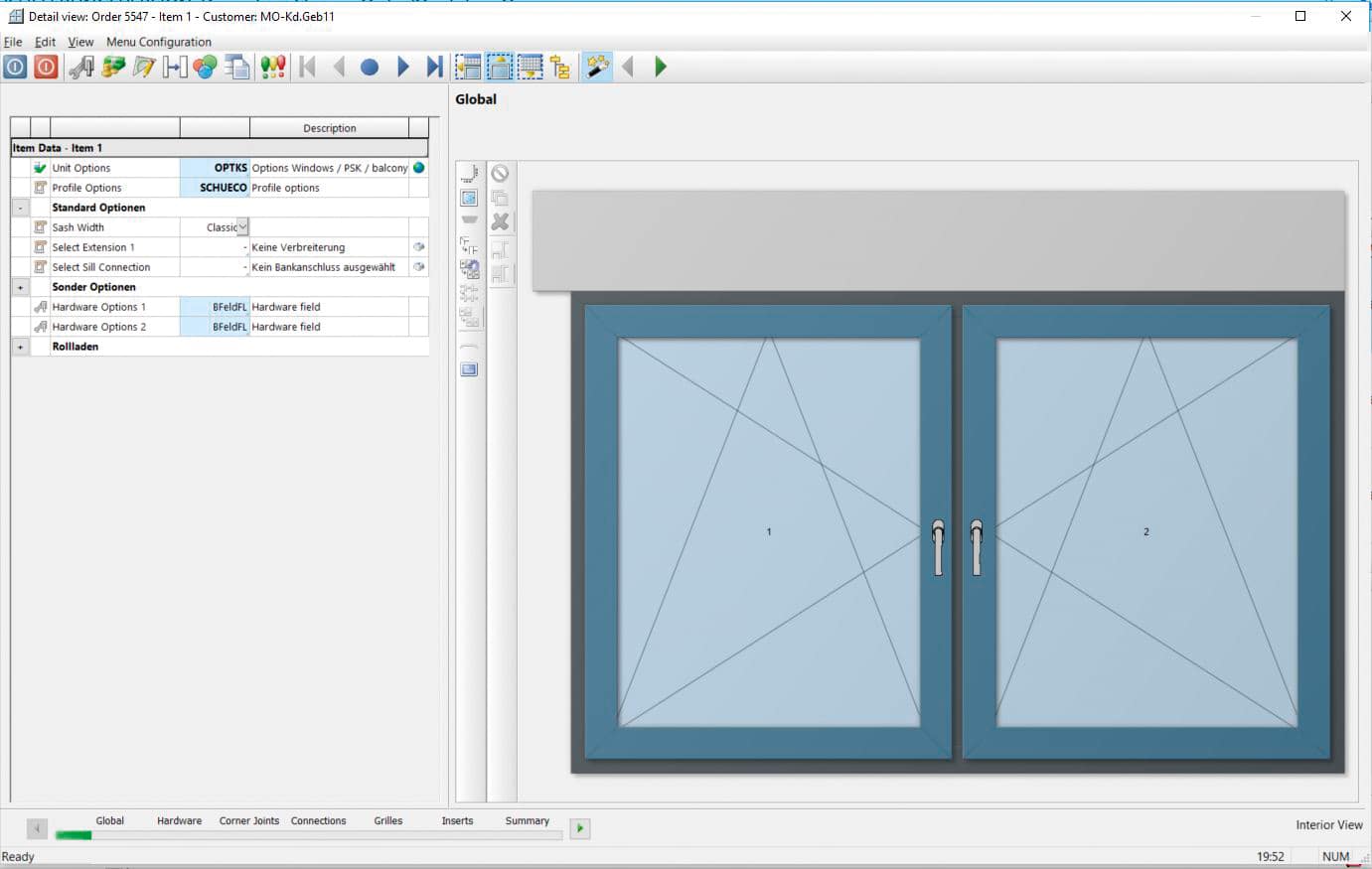

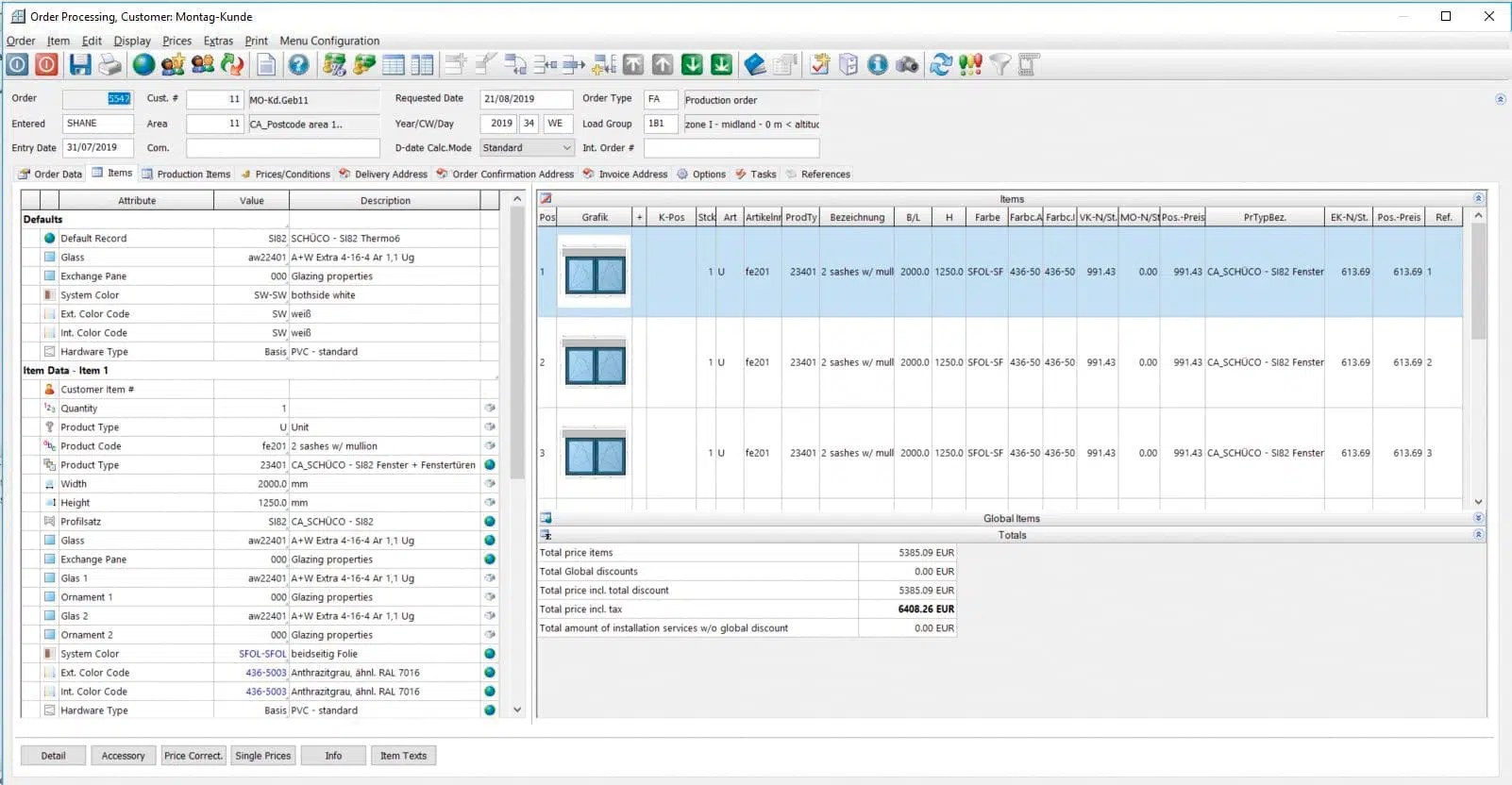

- Quotation and order processing allows entry of all materials for an order

- A+W Cantor conducts credit limit checks and considers individual delivery blocks before creating order confirmations

- Seamless integration with web configurators from adeco, dpi, OBUK, Rodenberg, ROMA, Schlotterer Sonnenschutz, and Warema ensures incorporation of the latest product offerings directly into the order entry process

- A remake order for customer complaints can be generated with just a few clicks in A+W Cantor, thus retaining reference to the original order

- The multilingual software allows you to serve customers around the world in their local language

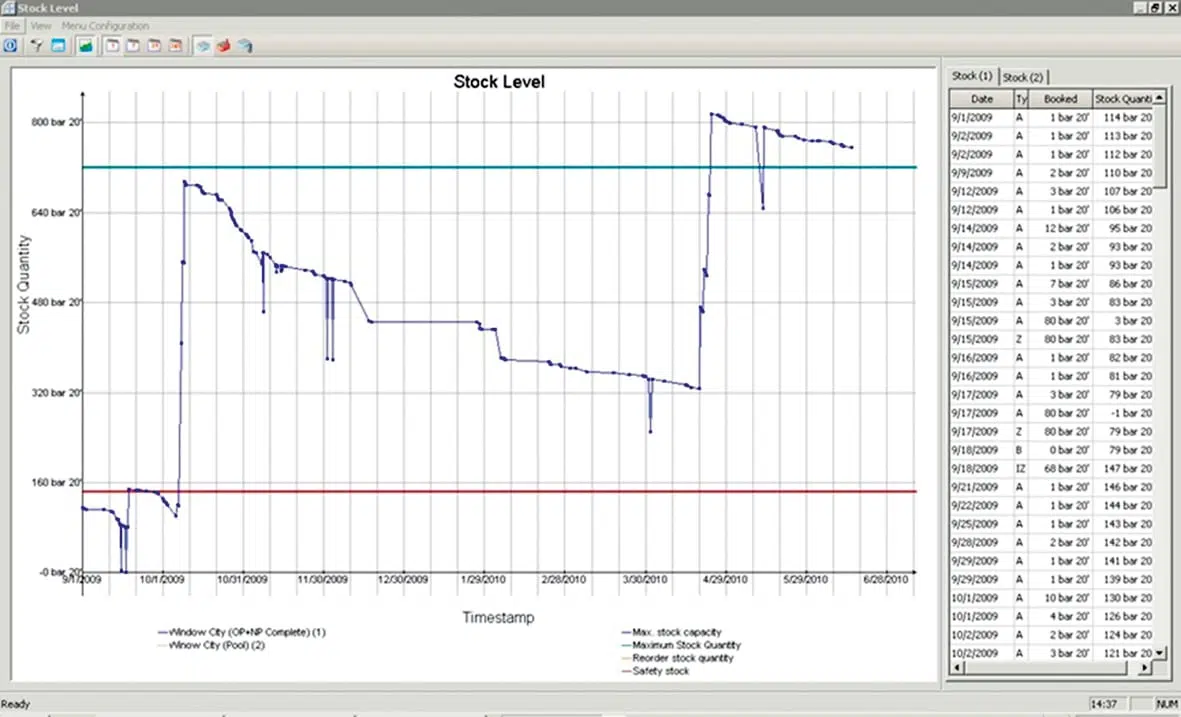

- Just-in-time ordering ensures materials arrive as late as possible yet as early as necessary

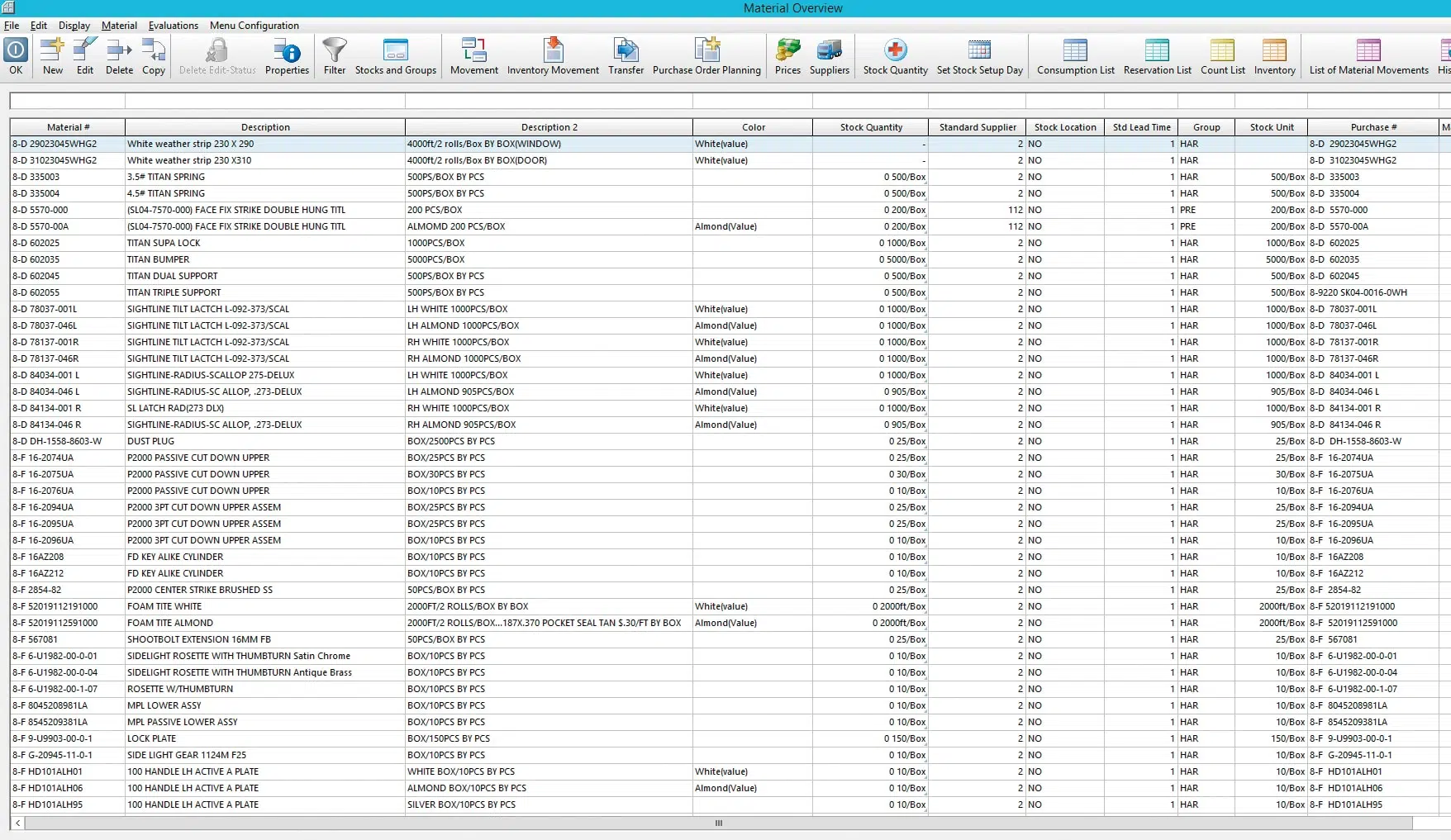

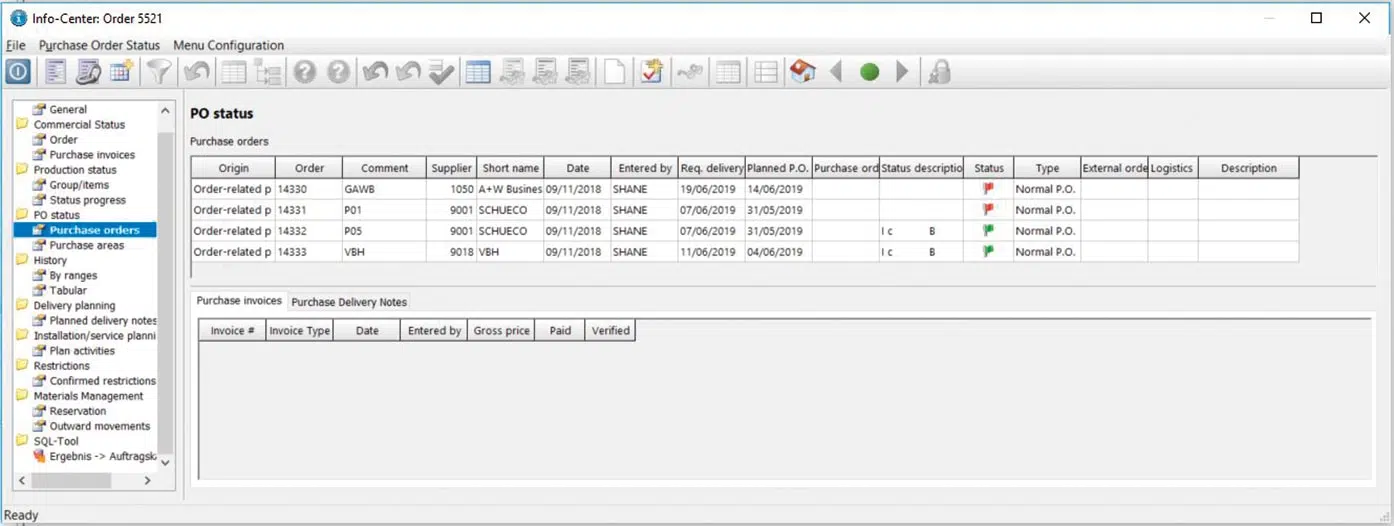

- Fully priced purchase orders and generated for stored suppliers for all order-related purchased materials

- Automated order management and electronic communication with suppliers are facilitated through openTRANS®

- Incoming and outgoing goods can be automatically booked or scanned using a mobile scanner

- A+W includes process improvement tools, such as workflow and task management, along with an info center, which facilitates company-wide optimization

- The integrated SQL tool allows for the creation of queries to analyze and optimize every area within the company

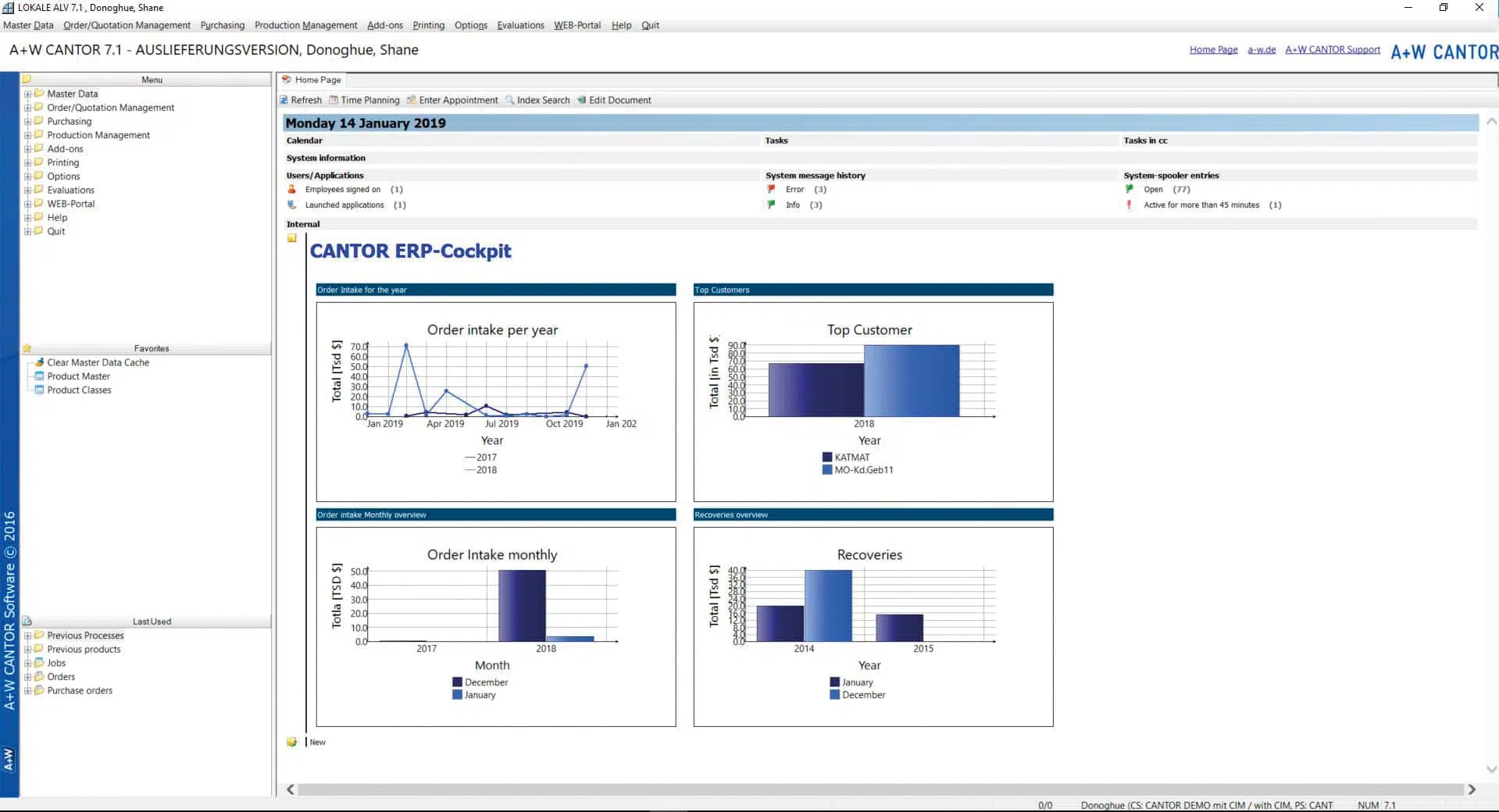

- Each user in A+W Cantor can create a personalized overview (cockpit), importing cross-divisional real-time evaluations for decision-making

- All documents and inter-departmental communication are stored within the system, promoting a paperless office, lean administration, and heightened efficiency

- Achieve paper-free operations through a digital documentation system

CIM – Integrated Modules & Business Processes

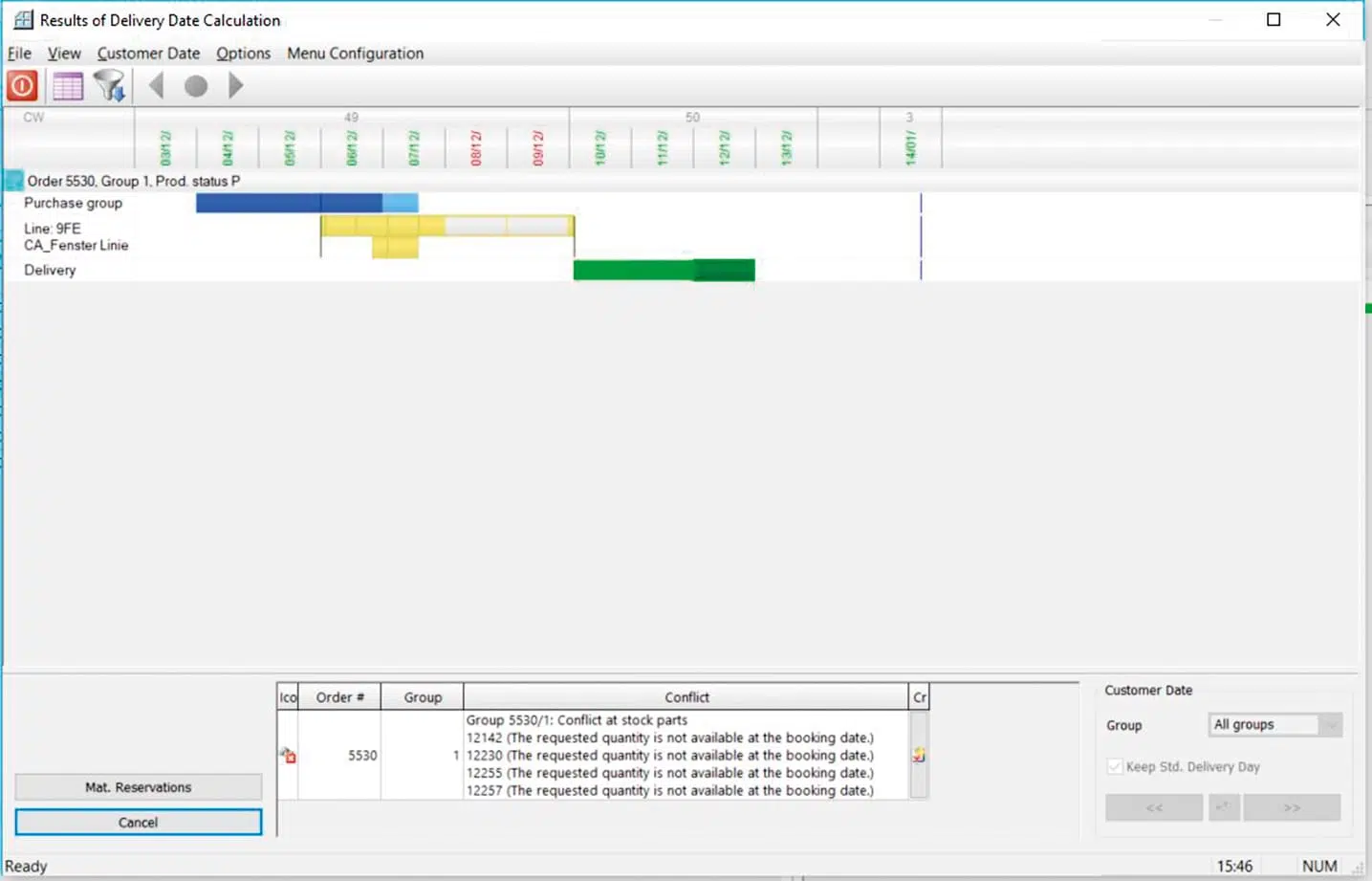

- Capacity planning and delivery date determination

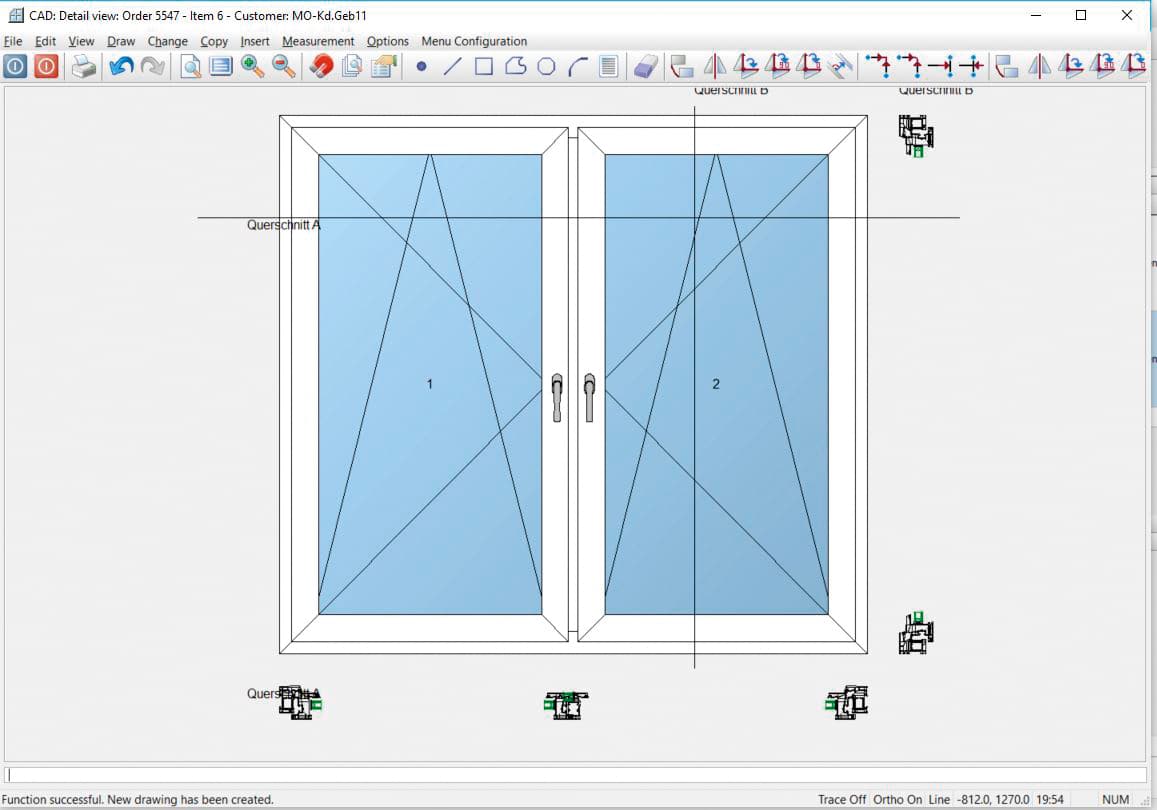

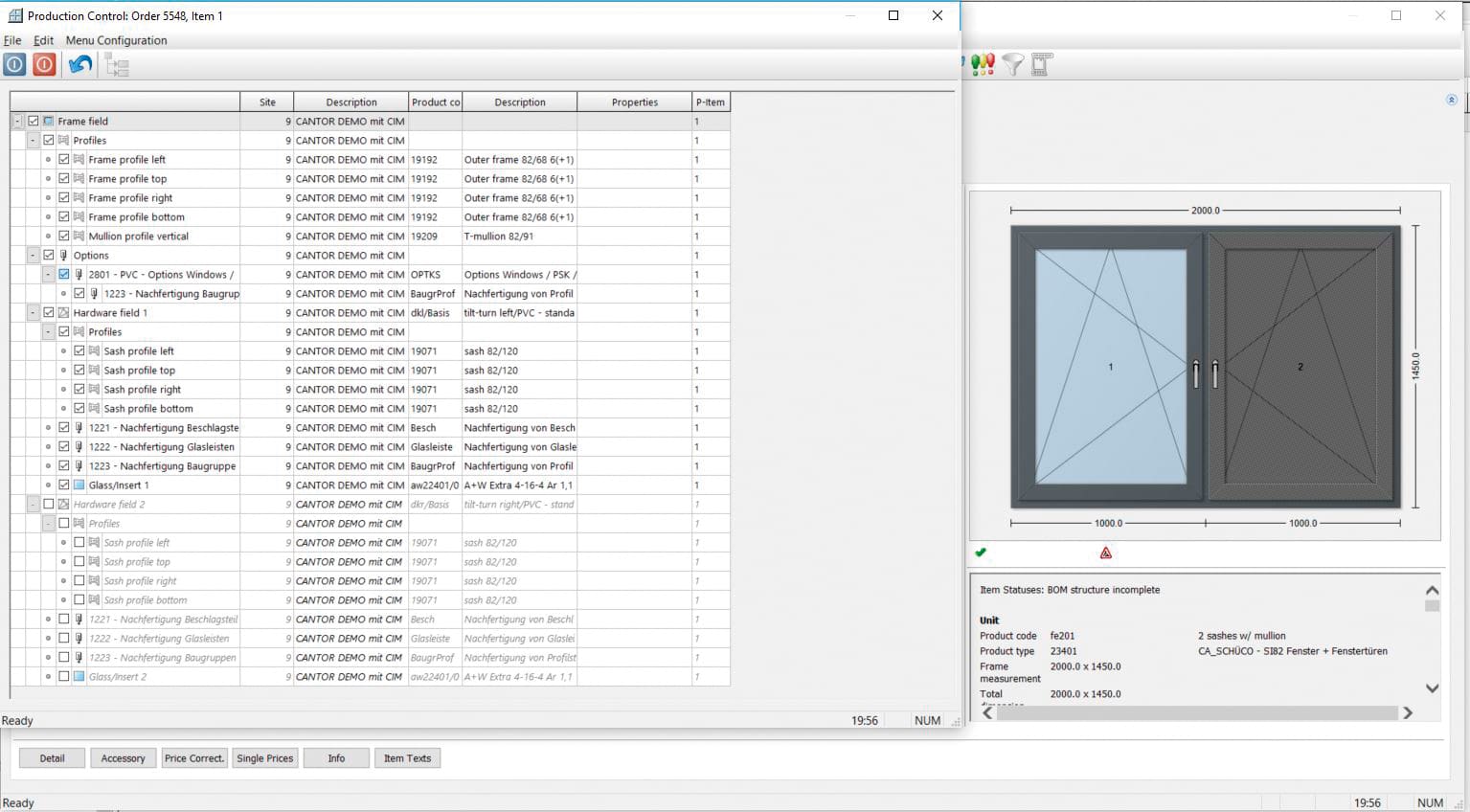

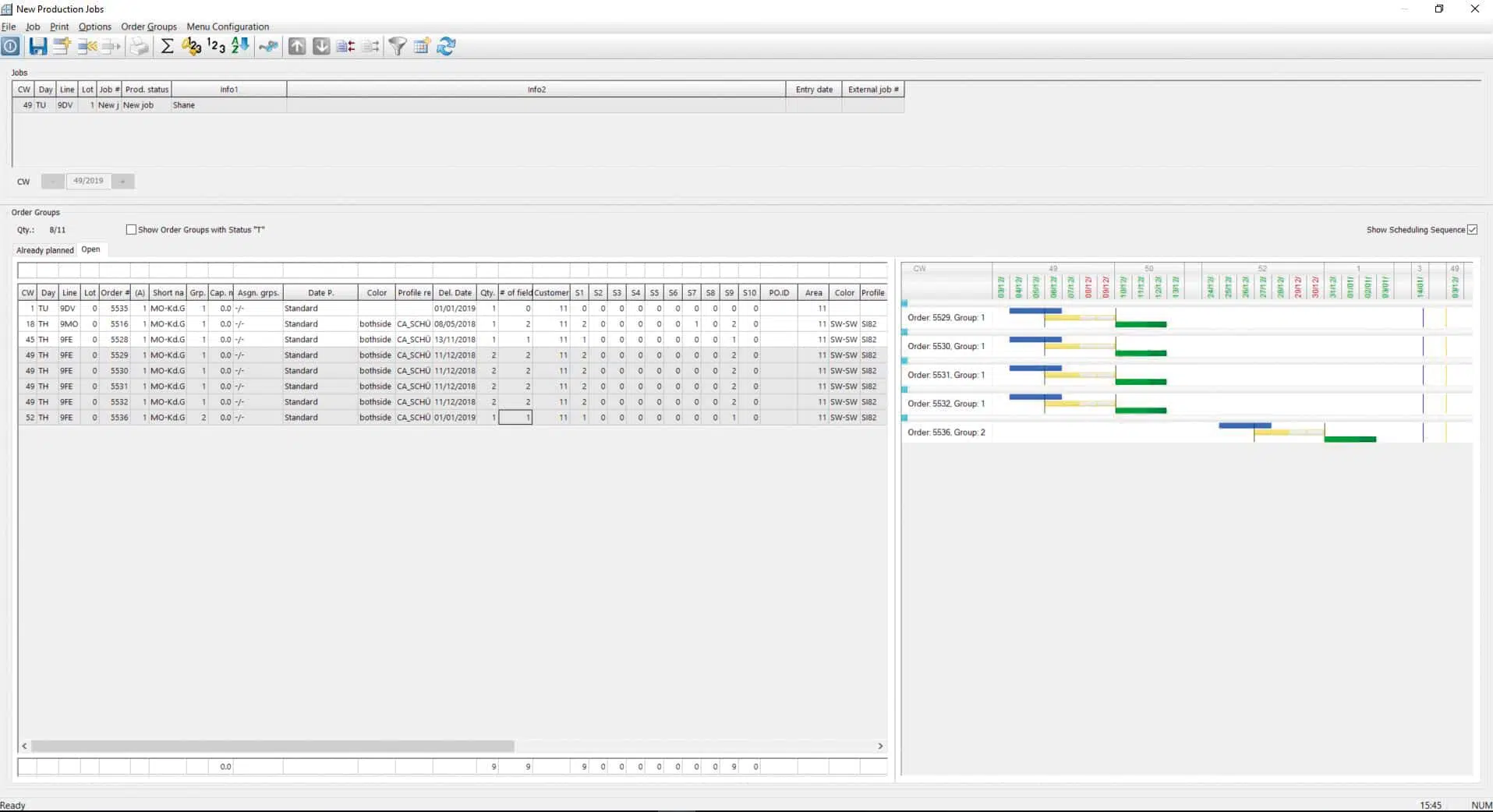

- Work preparation and production control

- Paperless manufacturing

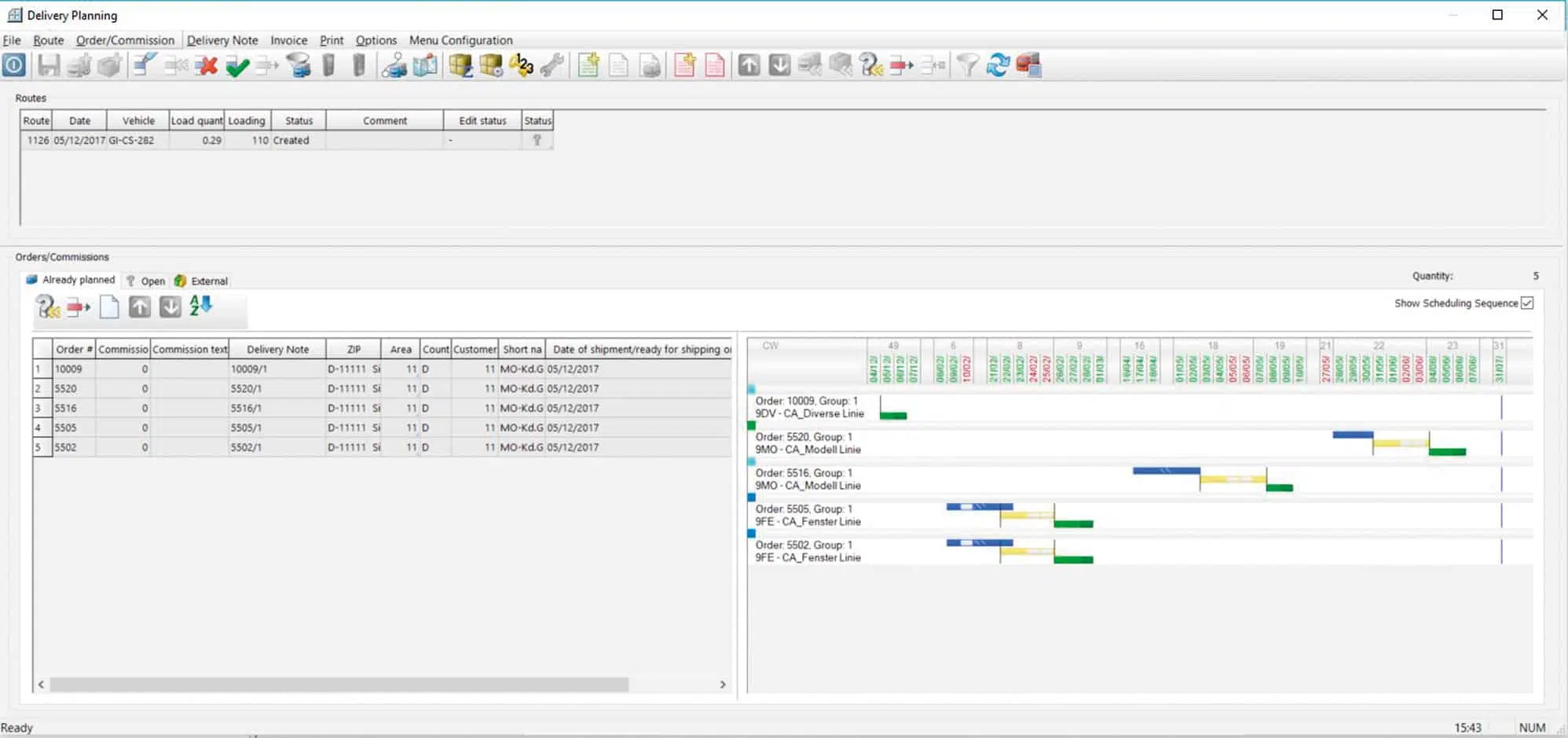

- Shipping and loading planning

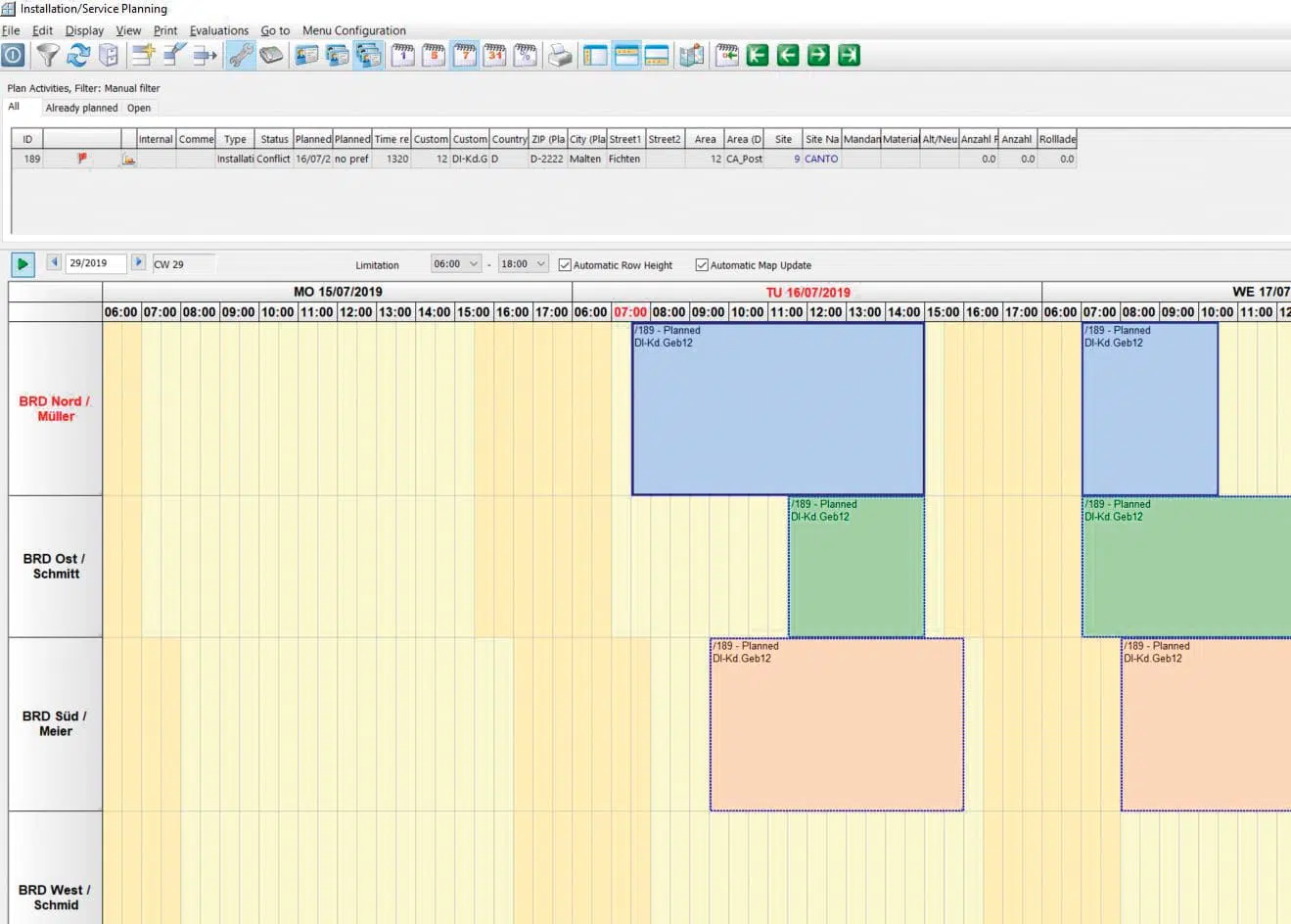

- Service and installation planning

- Order confirmations in A+W Cantor factor in production capacity and material requirements to determine precise delivery dates

- Just-in-time planning calculates tasks for all steps across departments, thus ensuring seamless coordination

- Flexible batch formation optimizes line capacity

- Cut optimization reduces material waste and costs

- Access all production-relevant information from labels to worksheets, directly within the system

- A+W Cantor manages machine control for streamlined production

- Increase efficiency and save time in the production process by eliminating the need for material and element searches

- Customize monitor displays to flexibly suit individual workplace requirements

- Access up-to-date digital worksheets anytime, thus eliminating errors caused by out-of-date documents

- Real-time tracing of materials and elements in production is enabled through continuous barcode usage

- A+W Cantor offers tools for customers to create personalized production cockpits, which are tailored to their needs

- Integrated plant-specific production control enhances efficiency

- A+W Cantor considers loading sequence in shipping rack preparation during production planning

- Pick lists detail storage locations for manufactured and , thus ensuring comprehensive loading for each truck

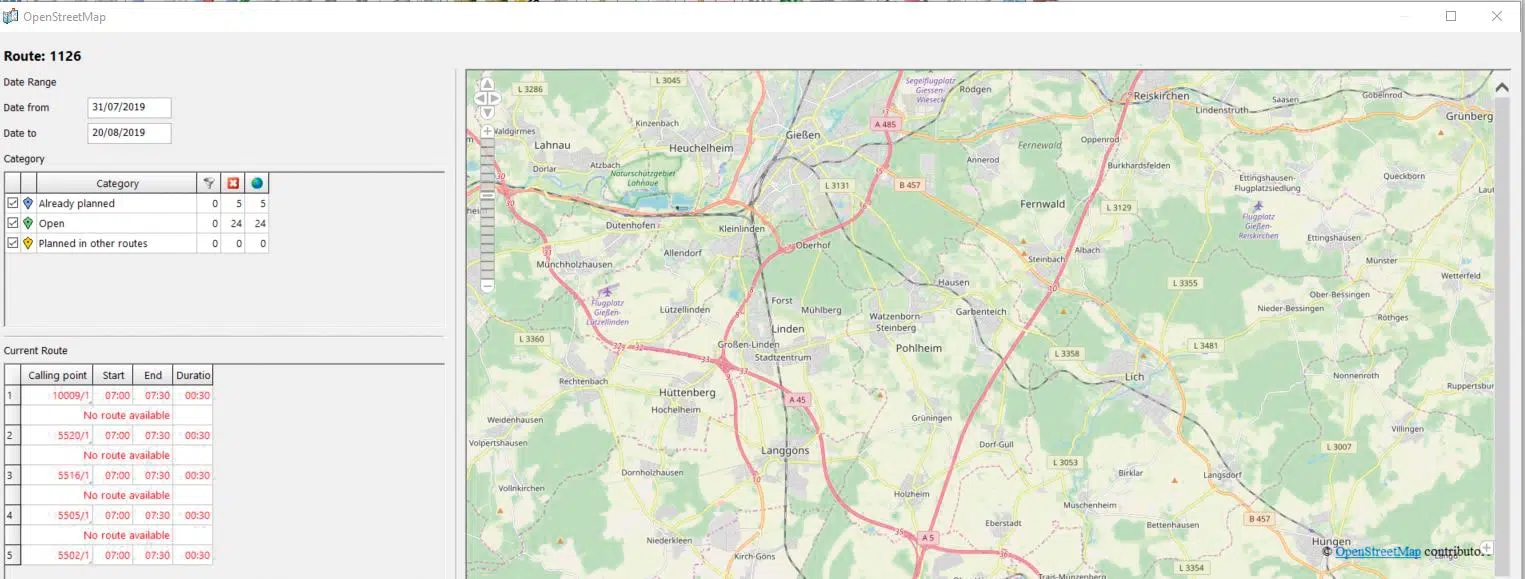

- Delivery route planning accounts for truck capacities, order weights, unit cargo areas, and preferred delivery days per area

- A+W Cantor offers warehouse organization with storage space management for finished elements, accessories, and purchased parts

- Automatically generate a plan during order creation, thus incorporating production scheduling

- The plan automatically accounts for the time and installation materials required for each order

- Geographic criteria are considered when assigning installation teams

- Appointments are automatically transferred to installation employees’ Outlook calendars

- Incorporation of OpenStreetMap provides geographic support

- Planned and actual times can be compared to create statistical evaluations

Satisfied Customer Voices

A+W Cantor Reference

AJM

The use of A+W Cantor by our retailers reduces the error ratio considerably, which saves us and the retailers lots of stress.

Read more

A+W Cantor Reference

Gugelfuss

There is no building block that we cannot handle with the A+W Cantor Software. We work almost 100% with A+W Cantor.

Read more

A+W Cantor Reference

Schlotterer Sonnenschutz Systeme

Our customers cannot make any more mistakes with A+W iQuote. The entire order runs through a restriction check based on our master data. We get a complete, technically correct order; questions and long-winded clarifications on the telephone are no longer required. This means greater efficiency in the entire order process” […] We set ourselves up for the future with a comprehensive ERP solution and we have never looked back. The A+W Cantor system offers us 100% availability and works absolutely reliably day after day.

Read more

Most Popular Add-ons

Cantor

iQuote

Your customers are accustomed to ordering products online 24/7. Leverage that buying habit utilizing A+W iQuote’s e-commerce store. This powerful e-commerce portal empowers window manufacturers to offer their dealers the convenience of generating quotations and placing orders for their customers, anytime, anywhere. Whether on-site at construction project or in the office, your dealers can access product configurations directly from your website, enhancing both customer service and optimized efficiency.

A+W iQuote seamlessly integrates with the A+W Cantor system, ensuring that data displayed in the e-commerce store is sourced directly from the A+W Cantor database. Orders placed through A+W iQuote are instantly visible in the A+W Cantor system, eliminating the need for duplicate order entry and enabling real-time scheduling for production.

- Seamless integration with A+W Cantor eliminates duplicate master data creation and maintenance for the e-commerce store

- Expansion of sales channels and customer reach

- Intuitive user interface requires no training

- Conduct price calculations and construction feasibility tests, mirroring A+W Cantor order entry

- Streamlined order processing, leading to faster and easier operations

- Direct transfer of e-commerce store orders for production planning

- Drastically reduced time-to-market for new products through web-based configuration

Cantor

A+W Cantor integrates administration and production: from creating quotations, entering orders, and production, on through to delivery and assembly, the whole process is mapped.

Our customers cannot make any more mistakes with A+W iQuote. The entire order runs through a restriction check based on our master data. We get a complete, technically correct order; questions and long-winded clarifications on the telephone are no longer required. This means greater efficiency in the entire order process” […] We set ourselves up for the future with a comprehensive ERP solution and we have never looked back. The A+W Cantor system offers us 100% availability and works absolutely reliably day after day.

With what we have created with A+W Cantor, we are the market leader when it comes to configurators.

Cantor

Cantor Smart Companion

A+W Cantor Smart Companion for A+W Cantor is currently available for both Production and Stock.

In the production area, utilize the app within the dispatch warehouse to efficiently book finished elements and accessories onto racks and allocate them to specific dispatch areas. Benefit from the continuous mode feature, thus allowing simultaneous scanning of multiple elements using the smartphone camera. Functioning as a mobile info terminal (read mode), the app provides valuable support by displaying production status updates for individual order items or objects located on racks. This ensures real-time tracking of element whereabouts during production. Material requisition is streamlined by scanning barcodes at predefined registration points.

Dynamic forms feature prominently in A+W Smart Companion, enabling user input via selection lists, checkboxes, sliding buttons, etc. Users have the flexibility to customize forms to suit specific requirements. Additionally, streamline complaint management by capturing complaints with accompanying photos directly within the app, thus seamlessly transmitting them to A+W Cantor CIM without redundant data entry.

Covering tasks in the stock area, including goods receipt, material transfer postings, and inventory postings, the mobile app, facilitates comprehensive refining of these processes. Easily access an overview of all counted items with data seamlessly integrated from A+W Cantor for immediate availability.

- Minimal learning curve thanks to the use of a familiar, everyday device

- Increased employee productivity facilitated by a user-friendly app

- Time-saving benefits achieved through rapid scanning of multiple barcodes (continuous mode)

- Gain an information advantage with quick and convenient access to element status and location at any time

Cantor

A+W Cantor integrates administration and production: from creating quotations, entering orders, and production, on through to delivery and assembly, the whole process is mapped.