Business

A modern ERP software solution that grows with you

Modern look and feel

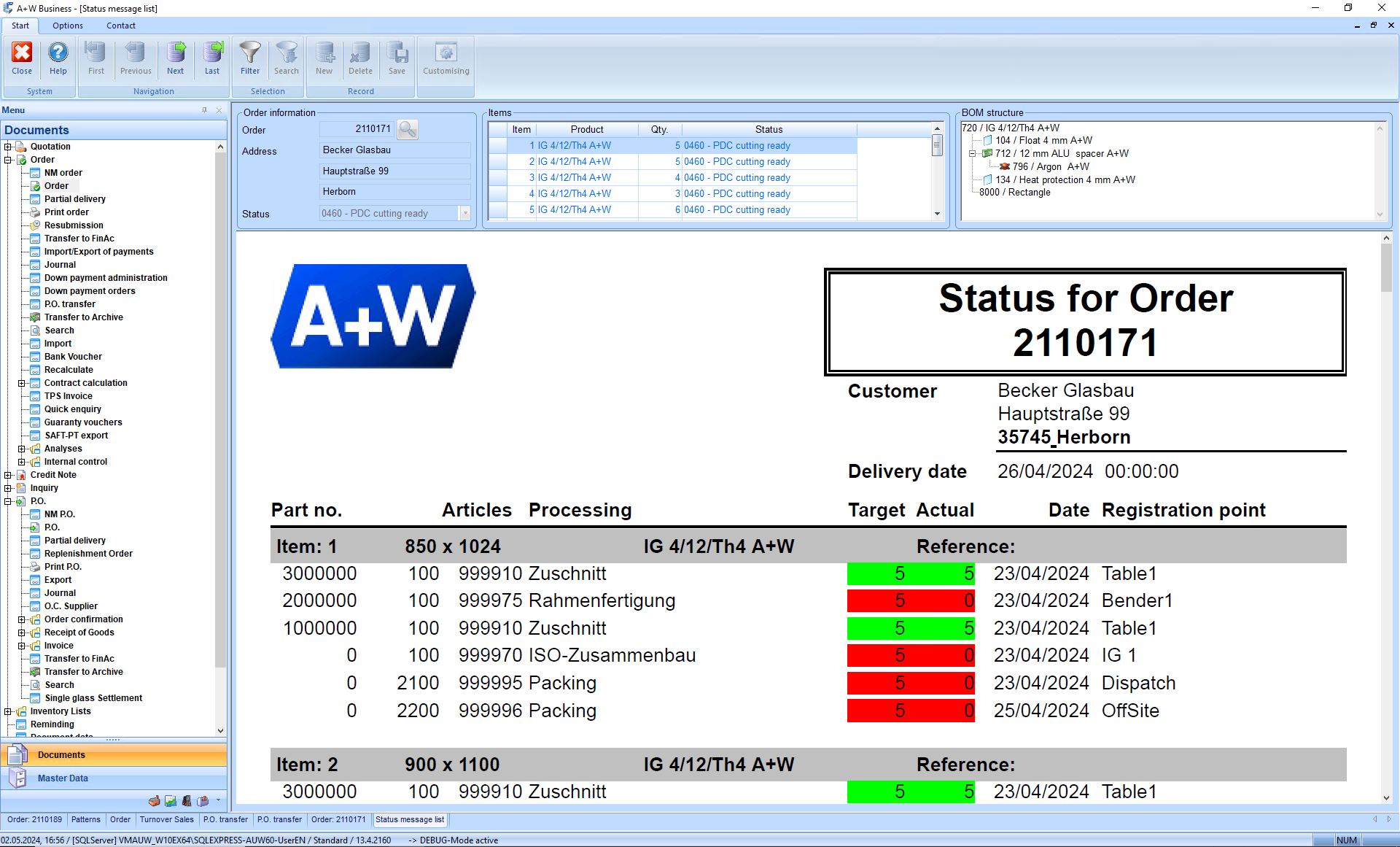

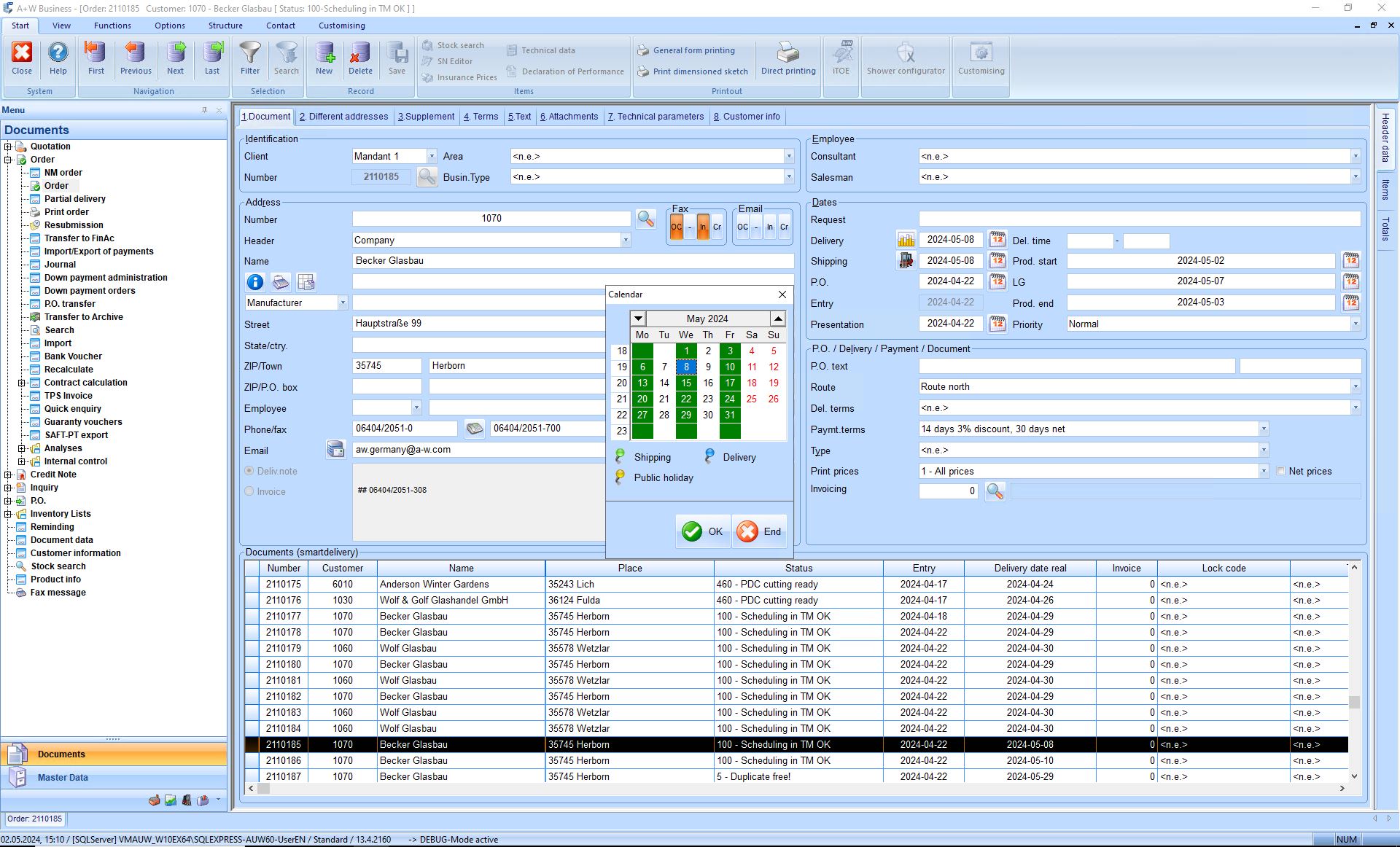

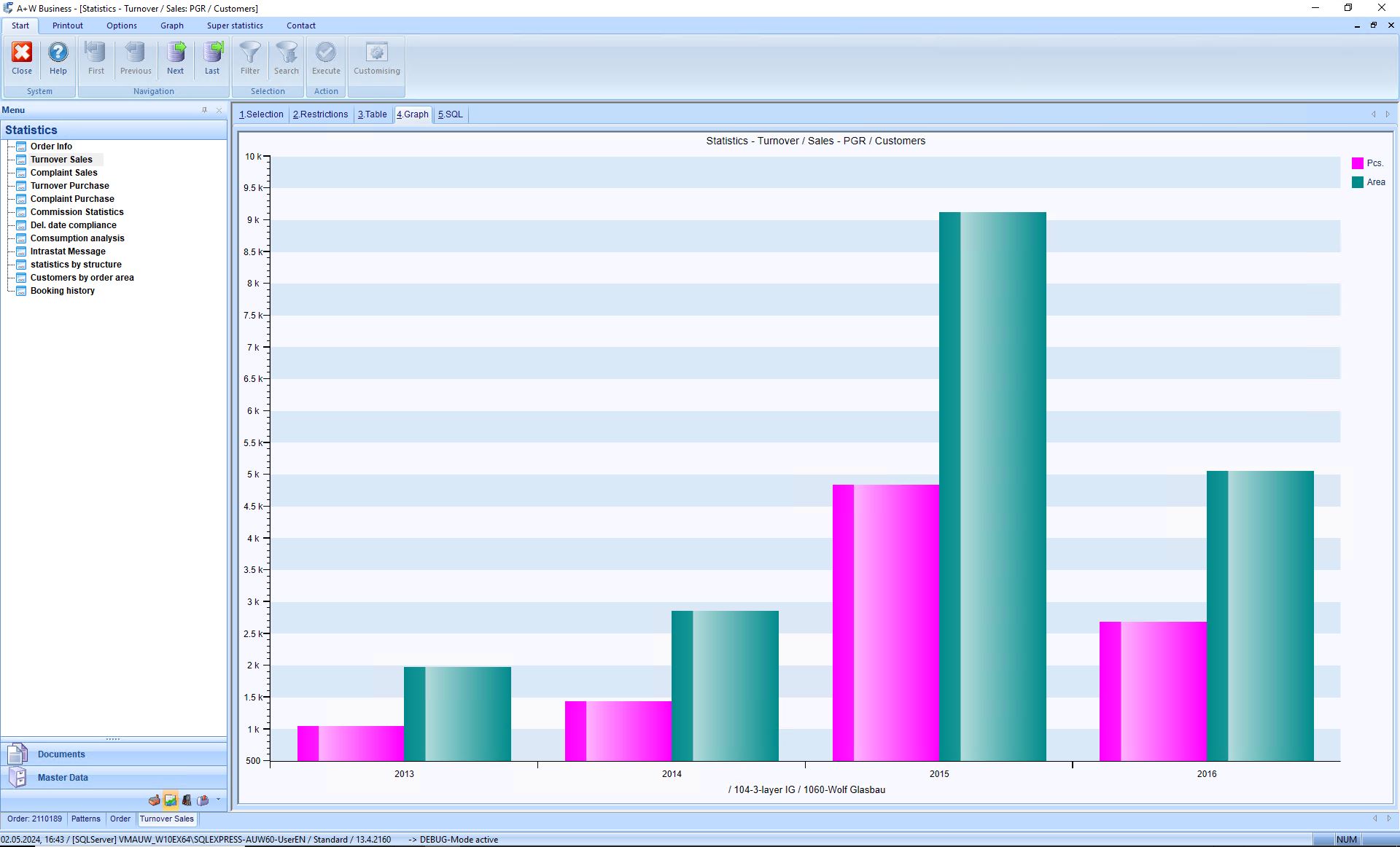

View important company data at a glance

Integrated calculation

Calculation of all components on the basis of purchase and sales price lists

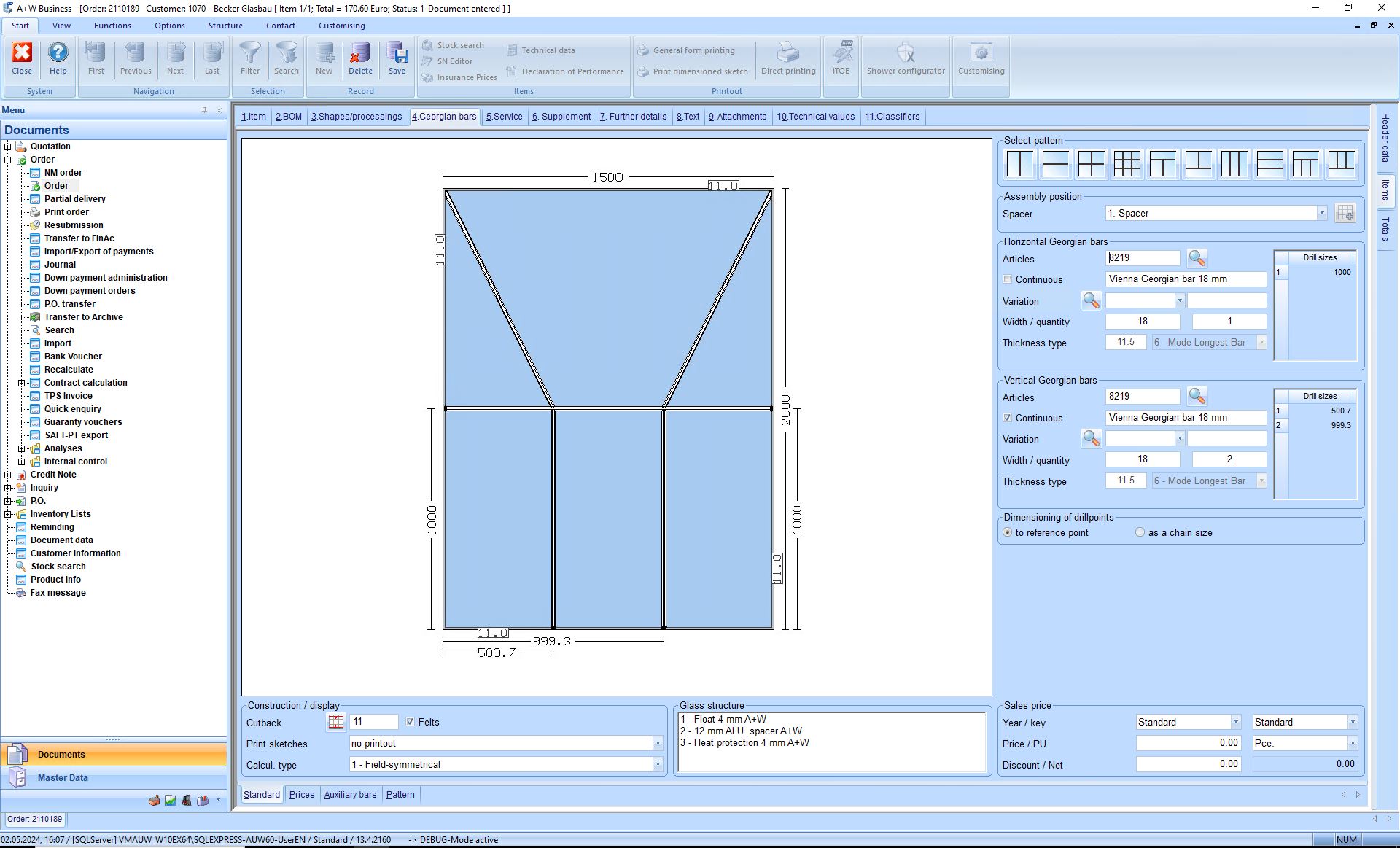

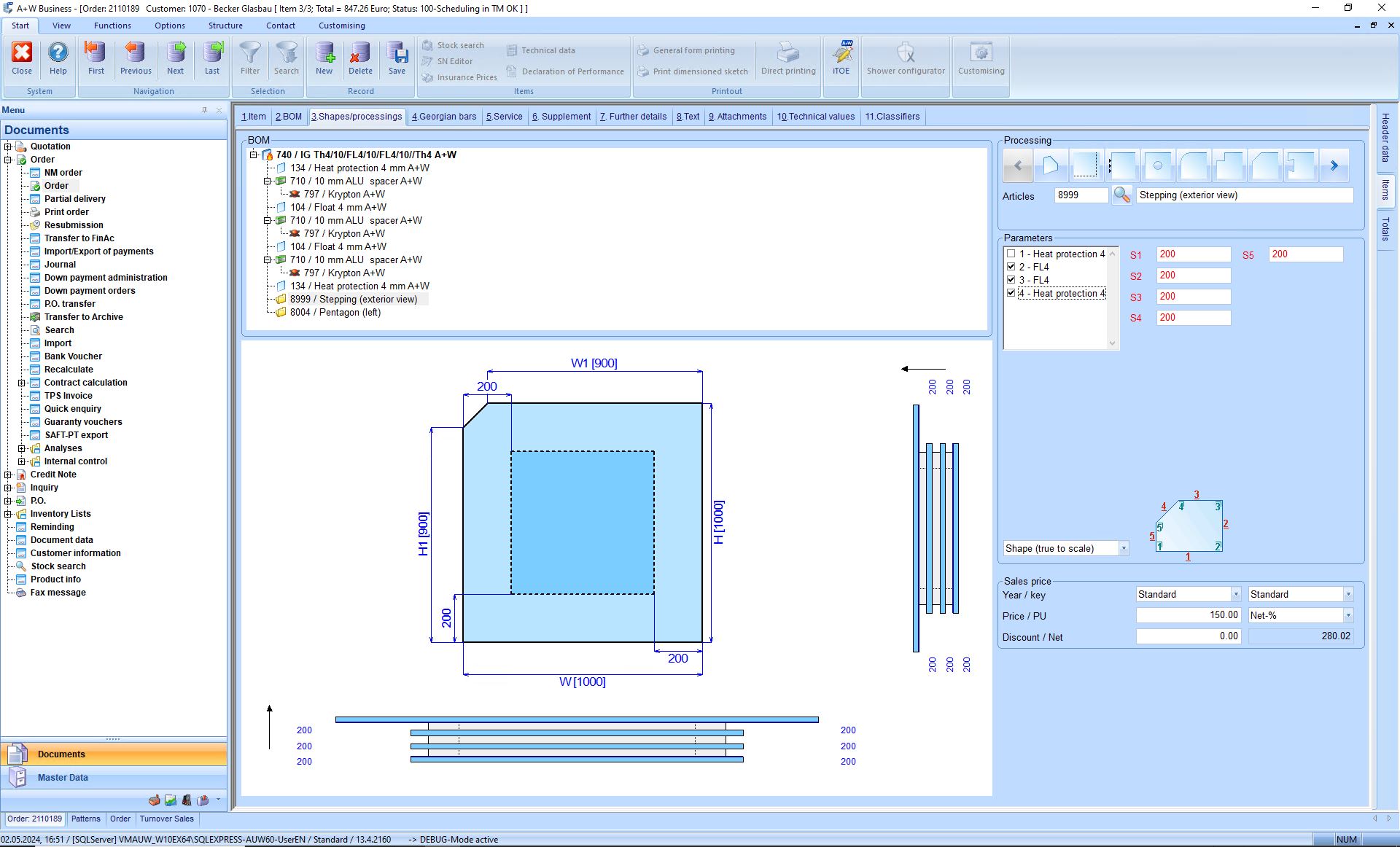

Technically advanced

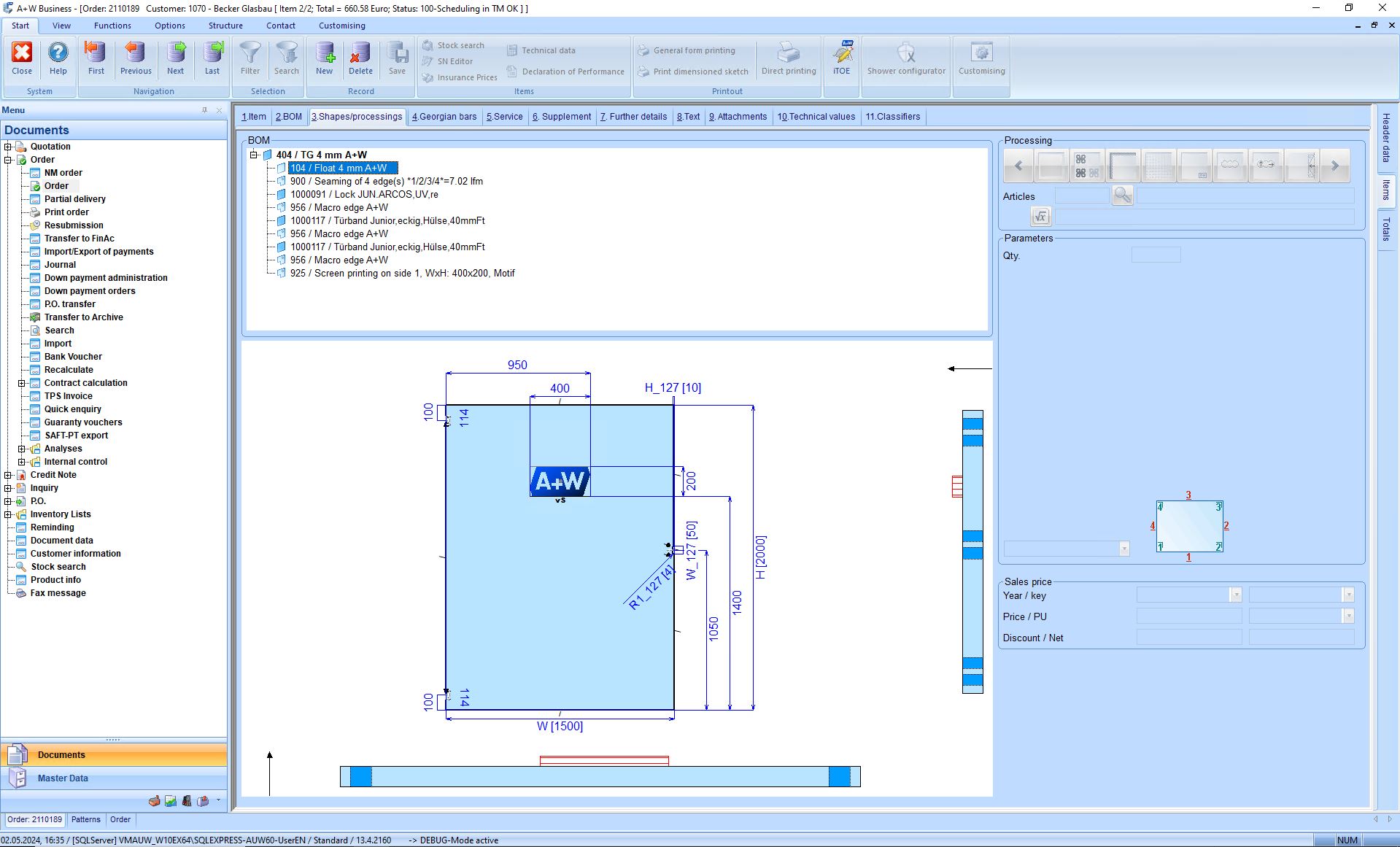

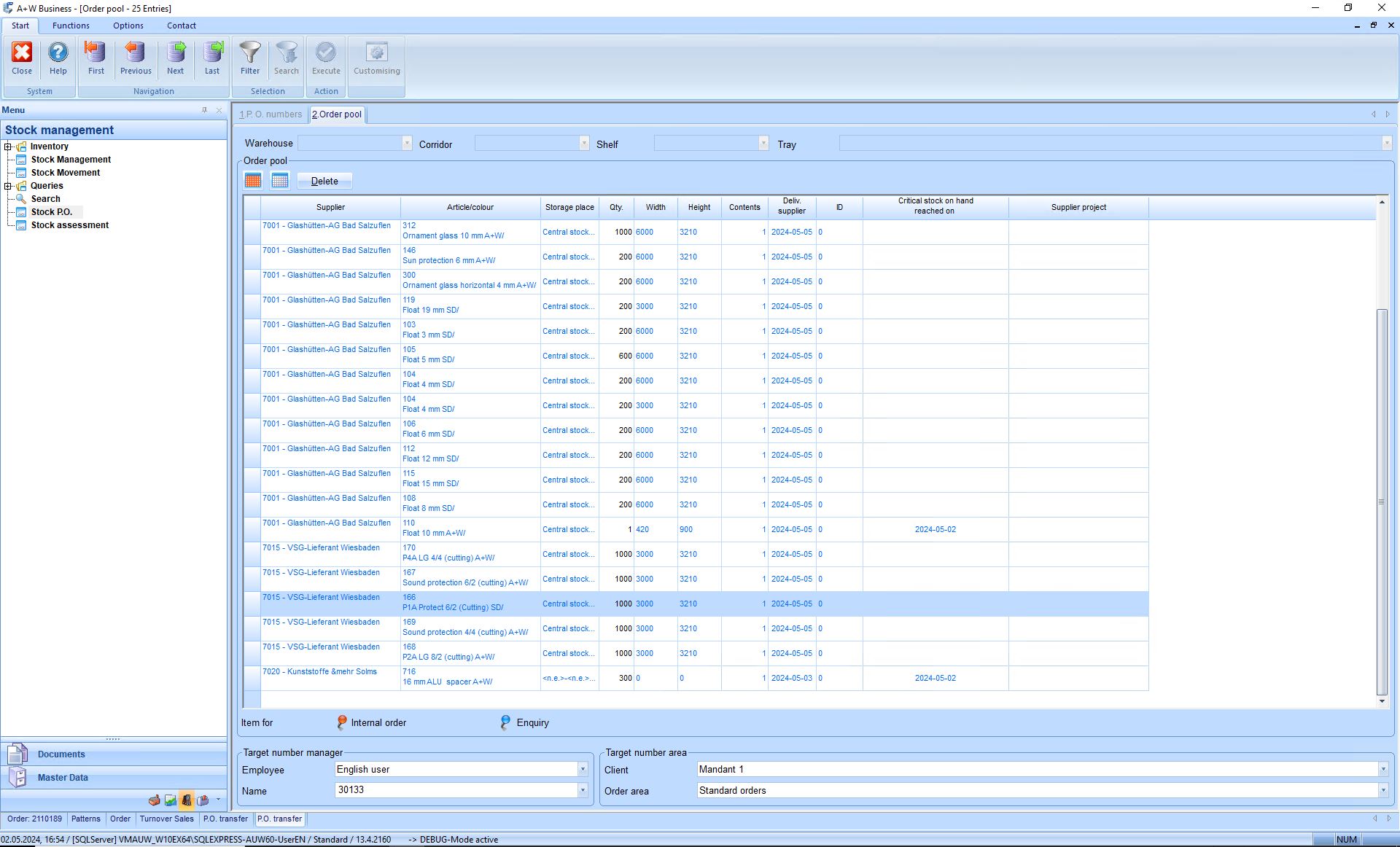

Special parts lists for smooth order processing

Automated

Automation through individually configurable workflows

About the Product

Functionality and ease of use are vital to your business success. We designed A+W Business to streamline your functions, including simple order entry and processing, which allows you to copy documents and generate automatic purchases or order proposals and an innovative parts list that can handle every part of a product tracking it throughout your facility.

Additionally features include the following:

(1) Our software smoothly connects with A+W Production, making it easy to transfer orders, purchase orders, and track production progress; (2) integrating A+W CAD Designer and standard shaping & machining catalog simplifies technical order input; and (3) our system supports swift and easy evaluations and analyses utilizing either Crystal Reports or QLIK reports.

Functionalities and Benefits

- Modern appearance

- Intuitive interface & processing steps

- Streamlined order processing

- Automation options

- Potential connection with A+W Production and A+W CAD Designer

- Quick and easy evaluations and analyses

Known for its modern approach, intuitive interface, powerful calculation capabilities, and advanced technical features, our solution is flexible, catering to both individual enterprises and conglomerates. With A+W Business, you gain access to a comprehensive software suite designed to streamline your business workflows and bolster managerial control over your company.

Satisfied Customer Voices

A+W Clarity Reference

Glas Schöninger

The A+W Barcode Tracking has taken our entire production organization to a new performance level. Only with it are we in a position to truly organize ourselves efficiently without long information paths, complicated inquiries, and time-consuming re-makes. Earlier, an employee frequently had to search for racks for hours in order to find a sheet if he was not sure whether or not it had been produced yet. Today, he just looks in the system – done!

Read more

A+W Clarity Reference

Caamaño CZ

The installation was performed without any problems. The A+W consultants have supported and advised us reliably during the implementation phase. I especially appreciate the frequent consulting in case of technical questions, which is provided by our A+W sales consultant Peter Kénesy with plenty of competence and patience.

Read more

A+W Clarity Reference

Float Glass Industries

High-quality innovative products are just not enough to be competitive as a glass processor. Requirements such as adherence to delivery dates, flexibility and short delivery times are becoming more and more important, competing in this vein with factors such as quality and costs. Lean processes and far-reaching IT support by our A+W system, which we have been successfully working with for many years, contribute considerably to our success in a fiercely competitive market.

Read more

Popular Add-ons

Clarity

Furnace Optimizer

A+W Furnace Optimizer introduces an intelligent solution for toughened safety glass production that aims to maximize furnace bed utilization and energy efficiency simultaneously. By reporting the availability of sheets prior to the glass tempering system, A+W Furnace Optimizer facilitates dynamic and efficient furnace bed occupancy.

This software solution conducts real-time optimization directly in front of the oven, ensuring cost-effective production based on available sheets. Providing a graphical display of furnace bed occupancy and seamless access to booked sheets, A+W Furnace Optimizer offers a user-friendly operation.

Integrated into the production data acquisition system, this software solution furnishes real-time production progress updates, thus enabling precise control of the furnace bedto optimize production processes and maximize machine utilization. With its dynamic, customizable functionality, emphasis on quality assurance, cost efficiency, A+W Furnace Optimizer emerges as the ideal solution for glass industry firms seeking to streamline production processes and bolster competitiveness.

- Graphic display of the furnace bed assignment for efficient monitoring

- Batch-by-batch production and booking of the furnace bed

- Online optimization directly in front of the furnace, based on the available sheets on racks

- Direct access to booked sheets on racks and slot carts via A+W Barcode Manager or A+W Production Terminal

- Ability to save and evaluate batch information in connection with A+W IoT - Smart Trace

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

Smart Companion

The A+W Smart Companion revolutionizes warehouse management and logistics in the glass industry through its versatile functions and user-friendly handling. This innovative solution is usable on a mobile device under iOS and Android, offering an intuitive menu navigation that enables easy operation. The A+W Smart Companion can be deployed on various smart devices according to requirements and offers the ability to scan multiple barcodes in continuous mode.

Supporting the entire value chain, the A+W Smart Companion contributes to its digitization, saving time and costs while making processes more flexible. Warehouse management can be digitized with the A+W Smart Companion Stock Module, allowing the use of smart devices as scanner hardware for capturing inputs, outputs, transfers, and changes. During inventory, the Inventory function of the warehouse module supports the process with useful filters, checklists, and dashboards to optimize and simplify the process.

- Runs under iOS and Android

- User-friendly menu guide

- Depending on requirements, can be used on different smart devices

- Scanning of several bar codes in continuous mode

- Continuous digital stock management

- Safe and secure inventory

- Record incoming goods and stock transactions quickly and without errors

- more efficient workflows, no unnecessary running around

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

iShape

For the production of non-rectangular or extra-large shapes, glass processors frequently receive hand-drawn templates on paper, cardboard, wood, etc. from their customer. In order to fabricate these non-rectangular or larger shapes, modern CNC machines require digital data.

To solve this problem, A+W, in conjunction with Viprotron, developed a user-friendly, easy-to-operate app called A+W iShape.

With A+W iShape you can use your smartphone to photograph the template. The only requirement is A+W’s L-shaped reference objects that have to be placed on the template. Once photographed, the app will digitize the template by transforming the shape into an easy to edit outline, ready to be imported into A+W CAD Designer.

What makes A+W iShape special? In contrast to older solutions, there is no need to calibrate the camera! A+W iShape works with any quality smartphone camera.

- Place the L-shaped reference objects to automatically detect the template/photographed object.

- The L-shaped reference objects help correct any distortions when photographing a template.

- Once photographed, the iShape file can be imported into A+W CAD Designer, where further edits can be done.

- Transfer the DXF file to your CNC machine and start the production.

- Quick, reliable digitalization of templates

- Use of a good smartphone camera instead of an expensive, heavy digital camera

- Automatic import of the photo into the A+W CAD Designer

- Smoothing of the contour via the A+W patented smoothing process

- Output as DXF or A+W CAD format (SN) for use in A+W ERP and control of your machines with quick transfer to CNC machines

- Reliable compensation of distortions thanks to the reference object

- No calibration of the camera required

- Automatic import of the photo into the A+W CAD Designer

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.

Production

A+W Production is an extremely flexible PPS solution for complete rough and detailed scheduling for insulated glass, tempered glass, and laminated glass production. The system allows planning and control of even the most demanding multi-level production flows.

Clarity

Logistics Optimizer

A+W Logistics Optimizer revolutionizes logistics in the glass industry through automatic route planning and optimization, thus providing an efficient solution for the delivery of glass products.

It automatically creates and optimizes routes and delivery addresses, saving time and money. Based on Nokia Maps, A+W Logistics Optimizer considers truck restrictions and current traffic data to calculate optimal routes, ensuring efficient deliveries.

The mobile app facilitates seamless communication between drivers and the ERP system, which allows for real-time delivery tracking via GPS and almost instant confirmation.

- Automatic creation and/or optimization of routes and delivery addresses & weight (2 modes)

- (Re)calculation based on times, additional stops, and traffic

- Consideration of truck restrictions, tunnels, and traffic

- Printout reports for truck drivers and customs

- Mobile app for drivers and online delivery tracking via GPS

- Feedback to the ERP system possible (e.g., for printing delivery notes and invoices)

- Delivery statistics

- A+W Smart Delivery (delivery app) as a scalable solution, e.g., only for the electronic delivery invoice

Business

A+W Business is a complete ERP system for small and medium-sized companies. This commercial solution allows not just the entry of quotations, orders, credit notes, complaints, delivery notes, and the management of purchase orders and inquiries, but also control of other company areas (e. g. stock, purchasing, dispatch, etc.)

Business Pro

A+W Business Pro is a professional and cost-effective entry-level solution for small and medium-sized companies where order processing and production planning are completely integrated.

Enterprise

A+W Enterprise is a fully-integrated multi-site-capable ERP system for corporate groups and upscale medium-sized companies in the flat glass finishing industry.